gilukot nga singsing nga diyutay nga Die Titanium nga Nagpasaylo sa Bahin

Get Latest Price| Tip sa Pagbayad: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportasyon: | Ocean,Land,Air |

| Port: | NINGBO |

| Tip sa Pagbayad: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportasyon: | Ocean,Land,Air |

| Port: | NINGBO |

Brand: Krto

| Matang sa Pakete | : | Mga Bubble Bags, Carton, Mga Kahon sa kahoy |

The file is encrypted. Please fill in the following information to continue accessing it

Bugnaw nga init nga nakalimtan

Nag-espesyalista kami sa:

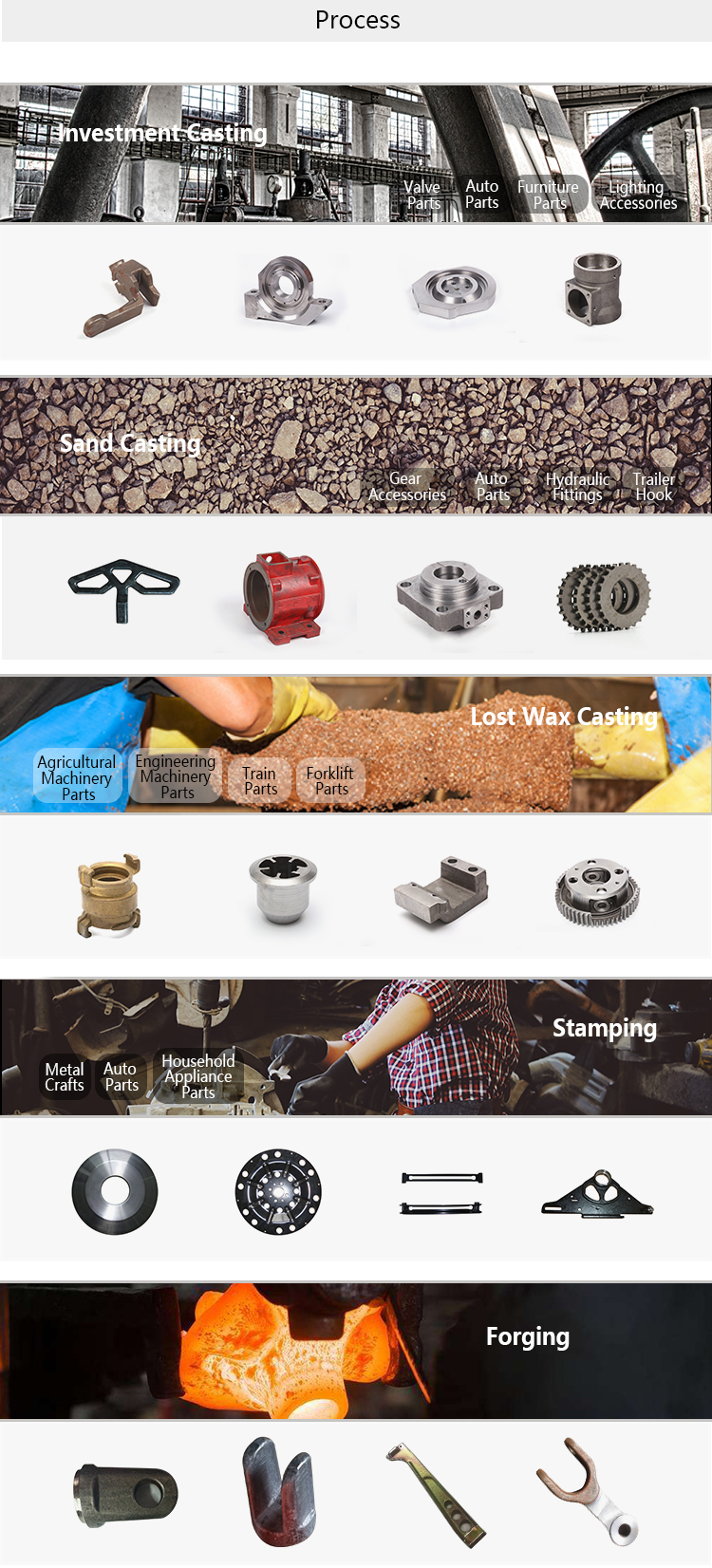

1. Sand Casting (grey iron, ductile iron, aluminyo, ug uban pa.)

2. Pagpamuhunan sa pagpamuhunan (carbon steel, stainless steel, Alloy Steel, ug uban pa.)

3. Die Casting (Aluminum, Zinc, ug uban pa)

4. Ang Machining (CNC Center, CNC LUTE, LATED DRIGNING Machine, Milling Machine, Pagpilit sa makina, uban pa)

Sertipiko: ISO9001: 2015, TS16949

|

Item Name

|

OEM customized rolled ring strainless steel casting die titanium forging part with investment casting

|

||

|

General Products

|

Metal Parts Solution for Vehicle, Agriculturemachine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

||

|

Process

|

Forging , Press

|

||

|

Blanks Tolerance

|

+/-0.3~+/-2 mm

|

||

|

Applicable Material

|

Carbon steel, Low Carbon steel, middle carbon steel, 40Cr, 20CrMnTi, 20CrNiMo etc.

|

||

|

Forging Blank Size

|

142 mm- 300mm or according to customer requirement

|

||

|

Blanks Weight

|

Range from 0.1kg-1000kg

|

||

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc.

|

||

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

||

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

||

|

Applicable Heat Treatment

|

Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

||

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting,

|

||

|

MOQ of mass production

|

100 pcs

|

||

|

Lead Time

|

25~45 days for steel forging metal parts

|

||

Pahayag sa Pagkapribado: Ang imong pagkapribado hinungdanon kaayo alang kanamo. Ang among kompanya nagsaad nga dili ibutyag ang imong personal nga kasayuran sa bisan unsang expany nga adunay tin-aw nga mga pagtugot.

Pun-a ang dugang nga kasayuran aron makontak ka sa imong paspas

Pahayag sa Pagkapribado: Ang imong pagkapribado hinungdanon kaayo alang kanamo. Ang among kompanya nagsaad nga dili ibutyag ang imong personal nga kasayuran sa bisan unsang expany nga adunay tin-aw nga mga pagtugot.